100%

Protection

1400+

Monitored machines

seamless

Integration

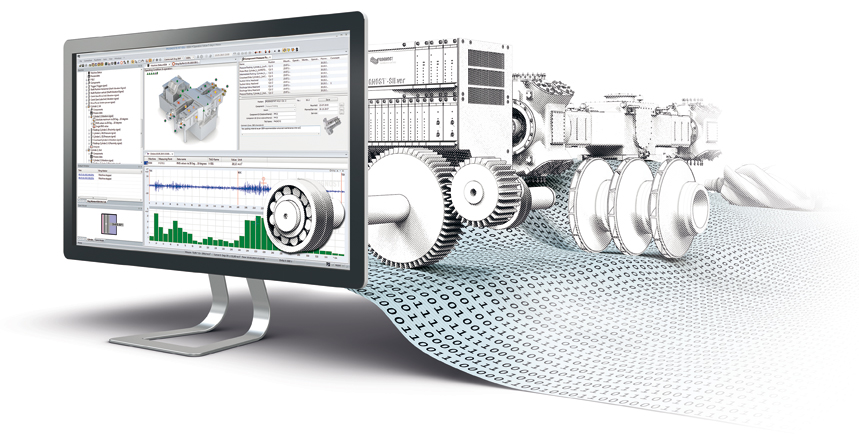

Our support provides the seamless integration of our systems in your plant

professional

approach

Continuous integration of user requirements and practical experience

client-centric

Focus

Customer-specific design, installation and individual commissioning

sustainable

Growth

More users show that our importance in the market increases constantly

client

testimonials

“PROGNOST is what it takes to have full compressor transparency.”

Ricardo Franco, Maintenance, BRASKEM, Brasilien

It All Starts With a consultation!

For any kind of quiries, Please call

Daimlerstraße 10, 48432 Rheine, Germany